TNF 2.0 system

- Home

- Construction Methods

- TNF 2.0 system

Low-Cost & Environmentally Friendly Soil Improvement Method

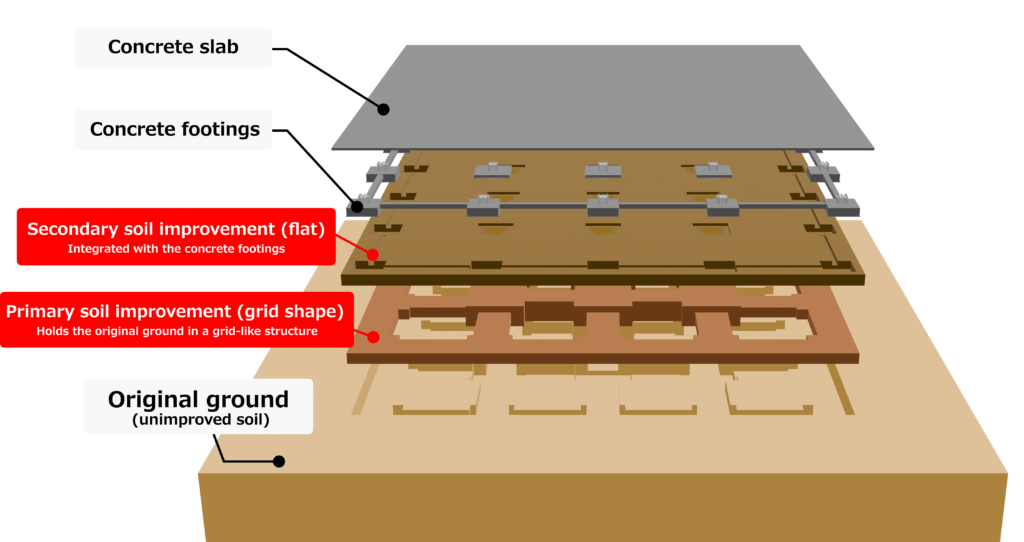

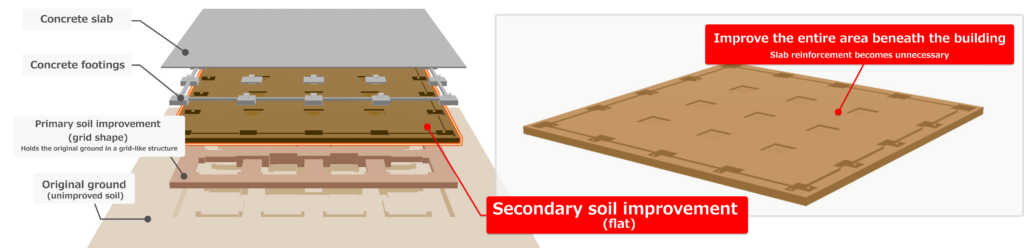

TNF 2.0 system is a type of shallow foundation that combines grid-shaped soil improvement, a concrete slab, and concrete footings.

By reducing construction processes and using general-purpose machinery, the TNF 2.0 system achieves shorter construction periods and lower costs.

Table of Contents

Soil Improvement Foundation Method

Patent

Title: 地盤改良体(Soil improvement body)

Patent number: No. 7175054

Date of registration: November 10, 2022

Tender = Environmentally friendly

Net = Grid structure

Foundation = Foundation

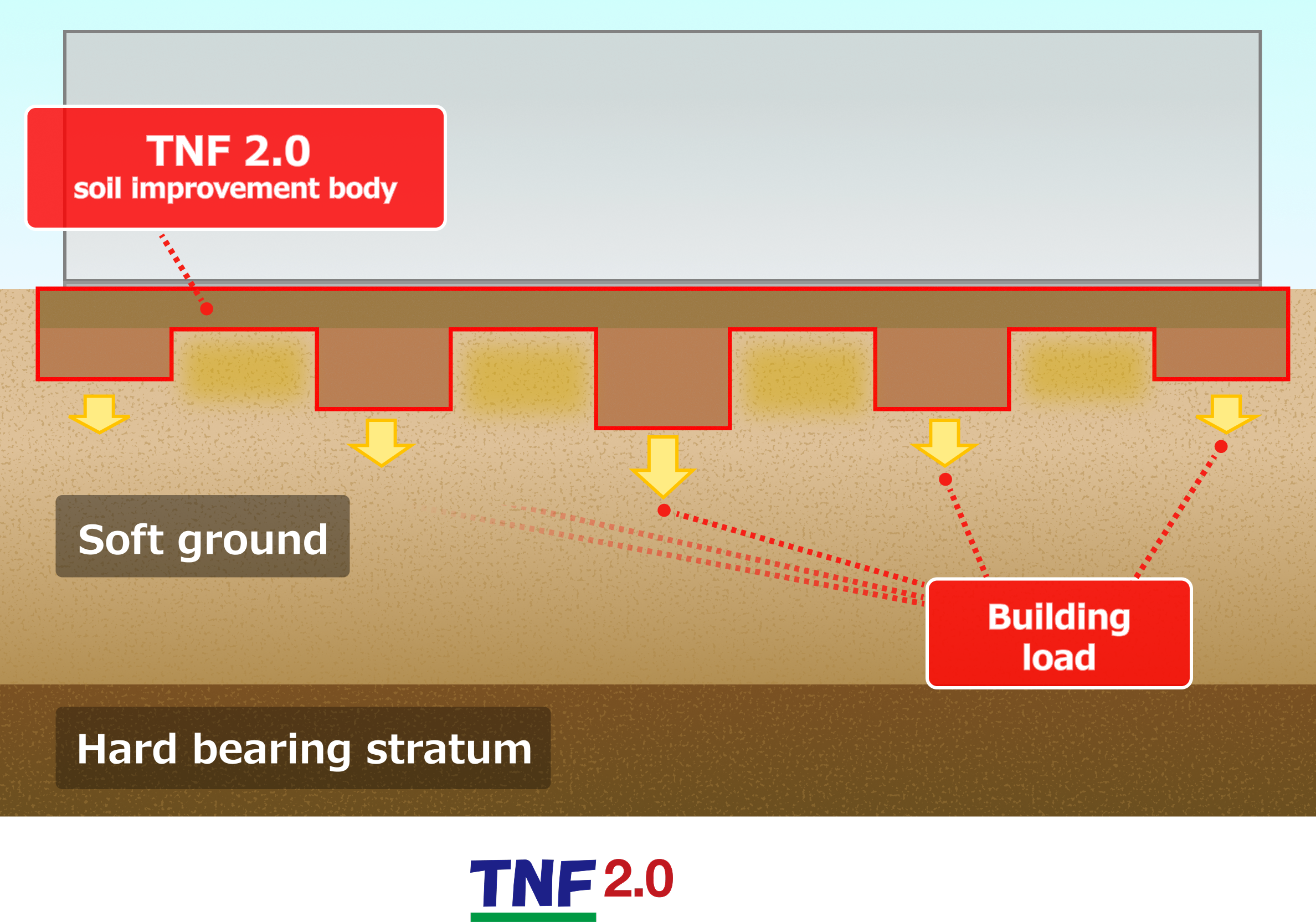

The TNF 2.0 system is a type of shallow ground improvement method. By improving the surface soil in a grid pattern and using it as a bearing layer, the TNF 2.0 system ensures structural stability. It is a low-cost and environmentally friendly method that requires fewer materials and fewer construction processes.

Integration of Soil Improvement, Concrete Slab, and Concrete Footings

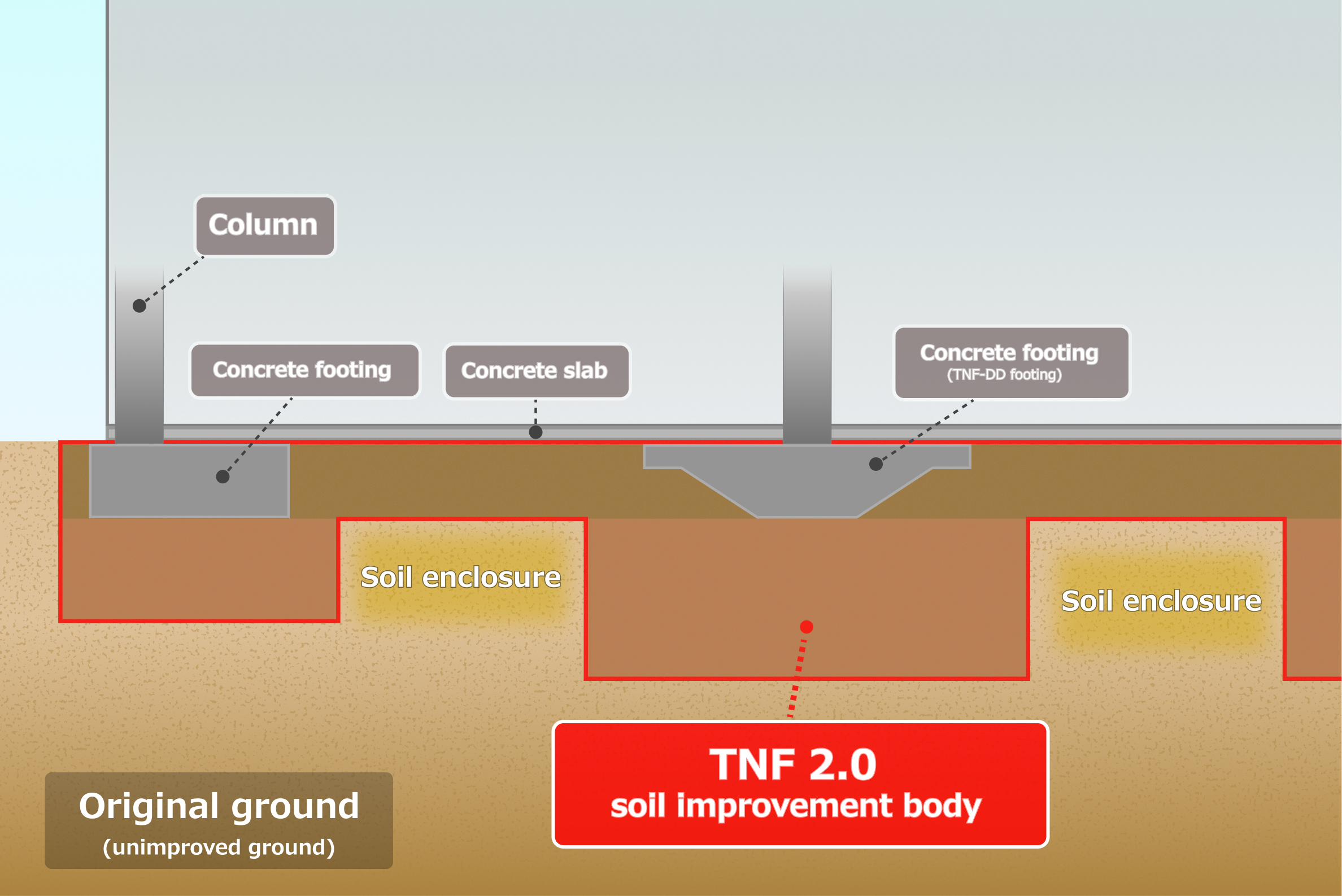

Enclosing the Soil by Grid-Shaped Soil Improvement

The grid-shaped soil improvement body confines the surrounding original ground, preventing soil from moving outward. As a result, shear deformation of the original ground enclosed by the grid walls is effectively suppressed.

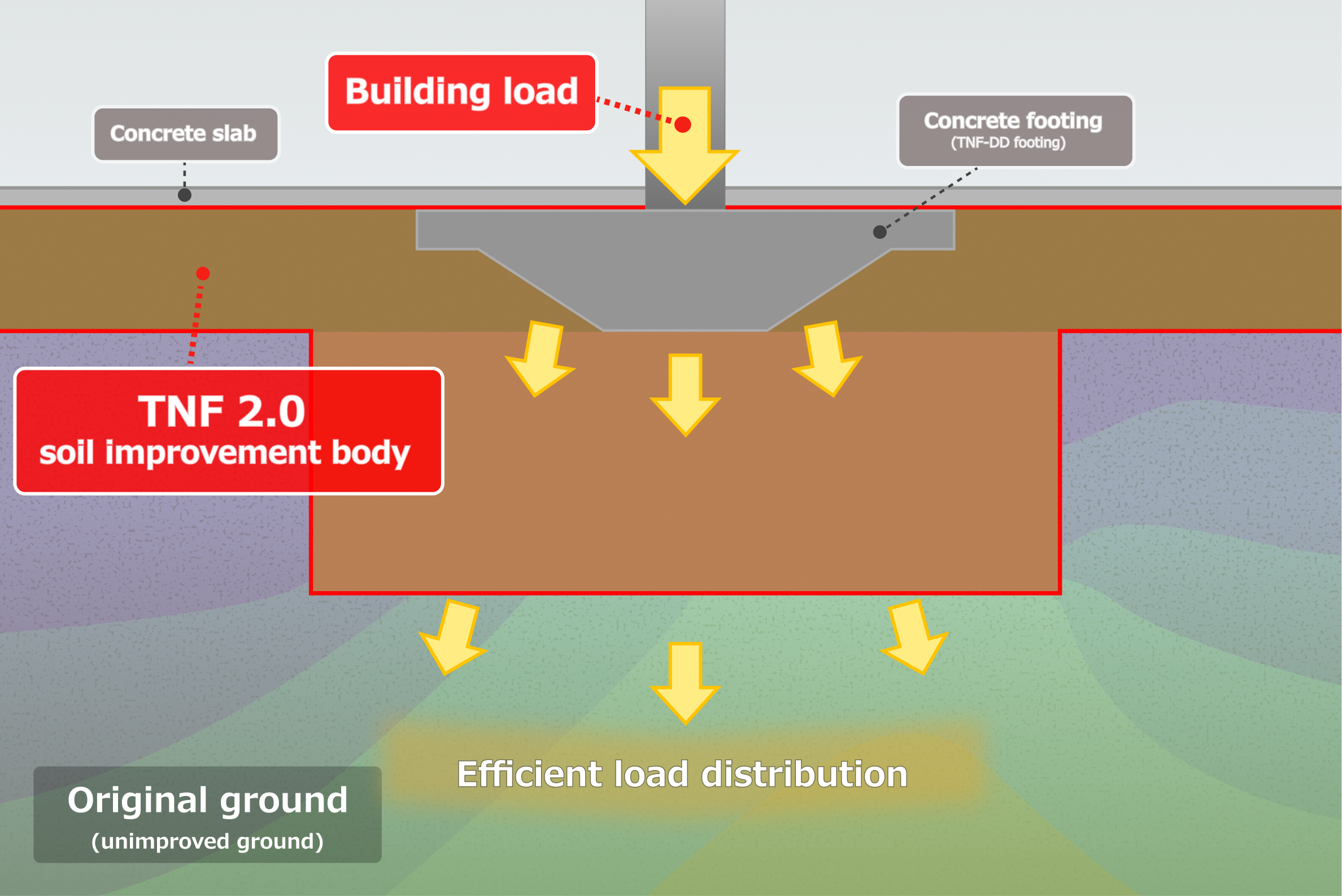

Distribution of Building Loads

By integrating the soil improvement, footings, and slab, the loads from the building are effectively transferred to the original ground.

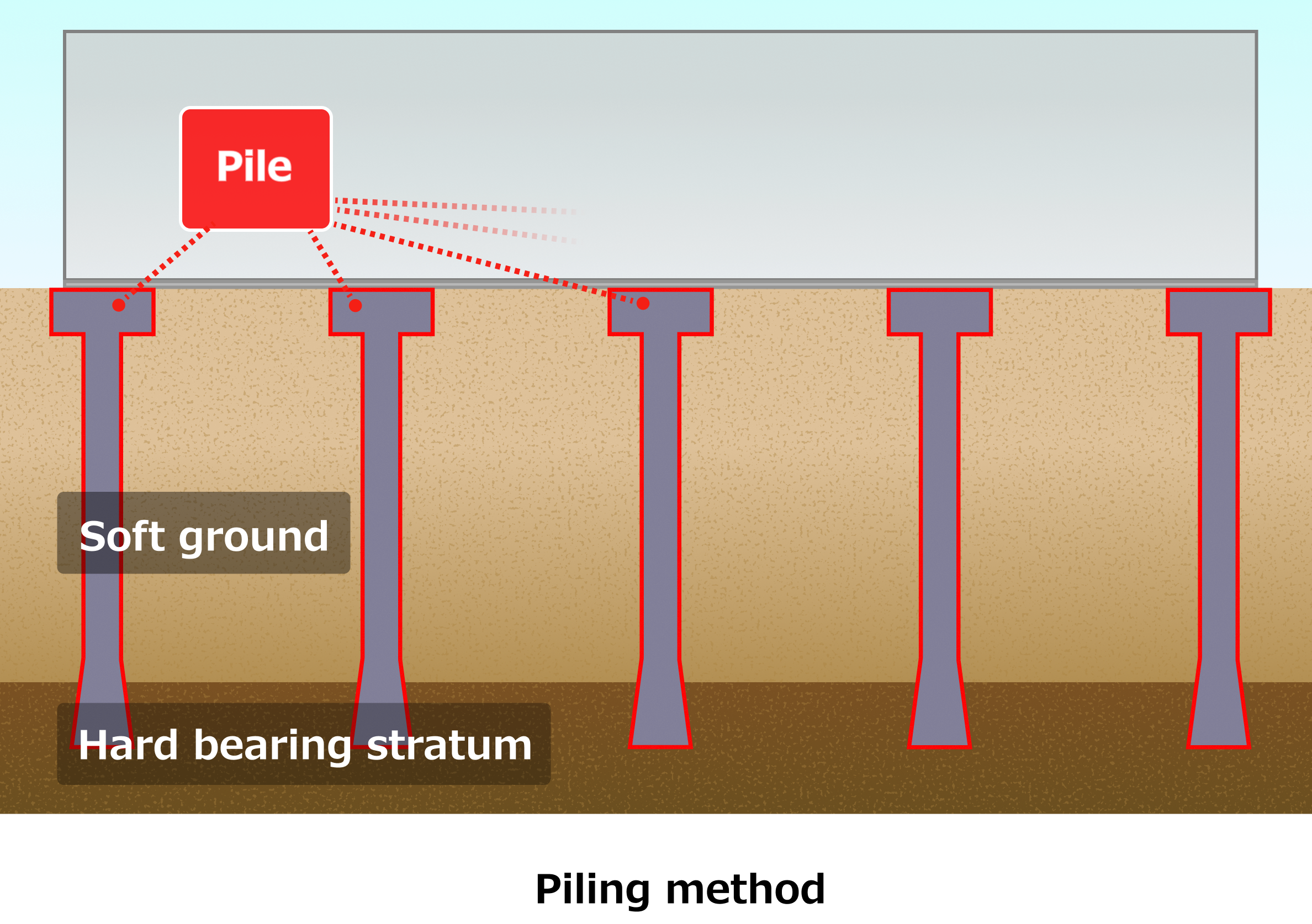

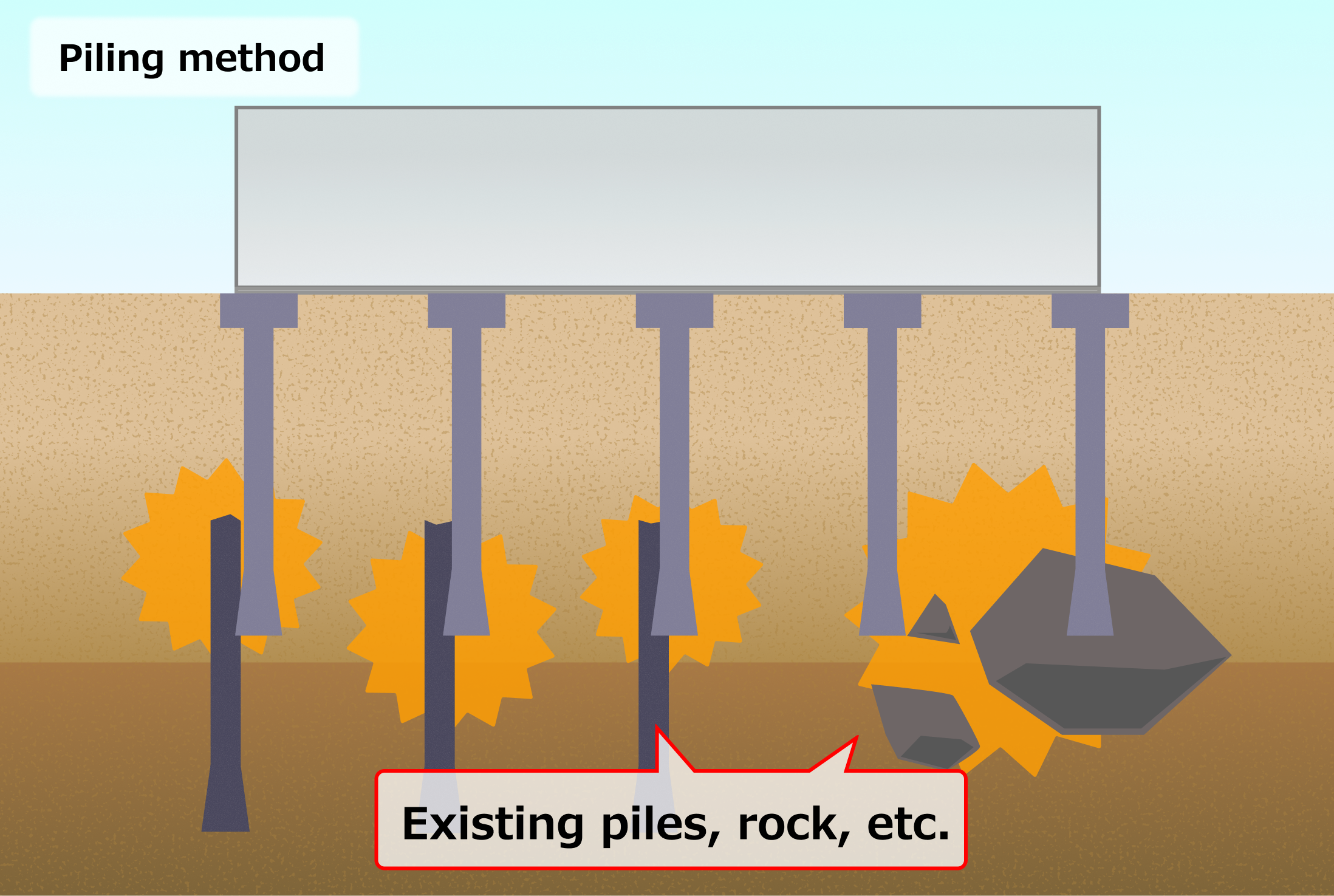

Low-Cost Foundation Without Piles

Traditionally, piles are driven through the upper soft ground to reach a hard bearing stratum. As a result, pile foundations are often time-consuming and costly. In contrast, the TNF 2.0 system improves the soft surface layer and uses it as the bearing layer, enabling a low-cost foundation without piles.

Differences Between the TNF 2.0 System and the Pile Foundation Method

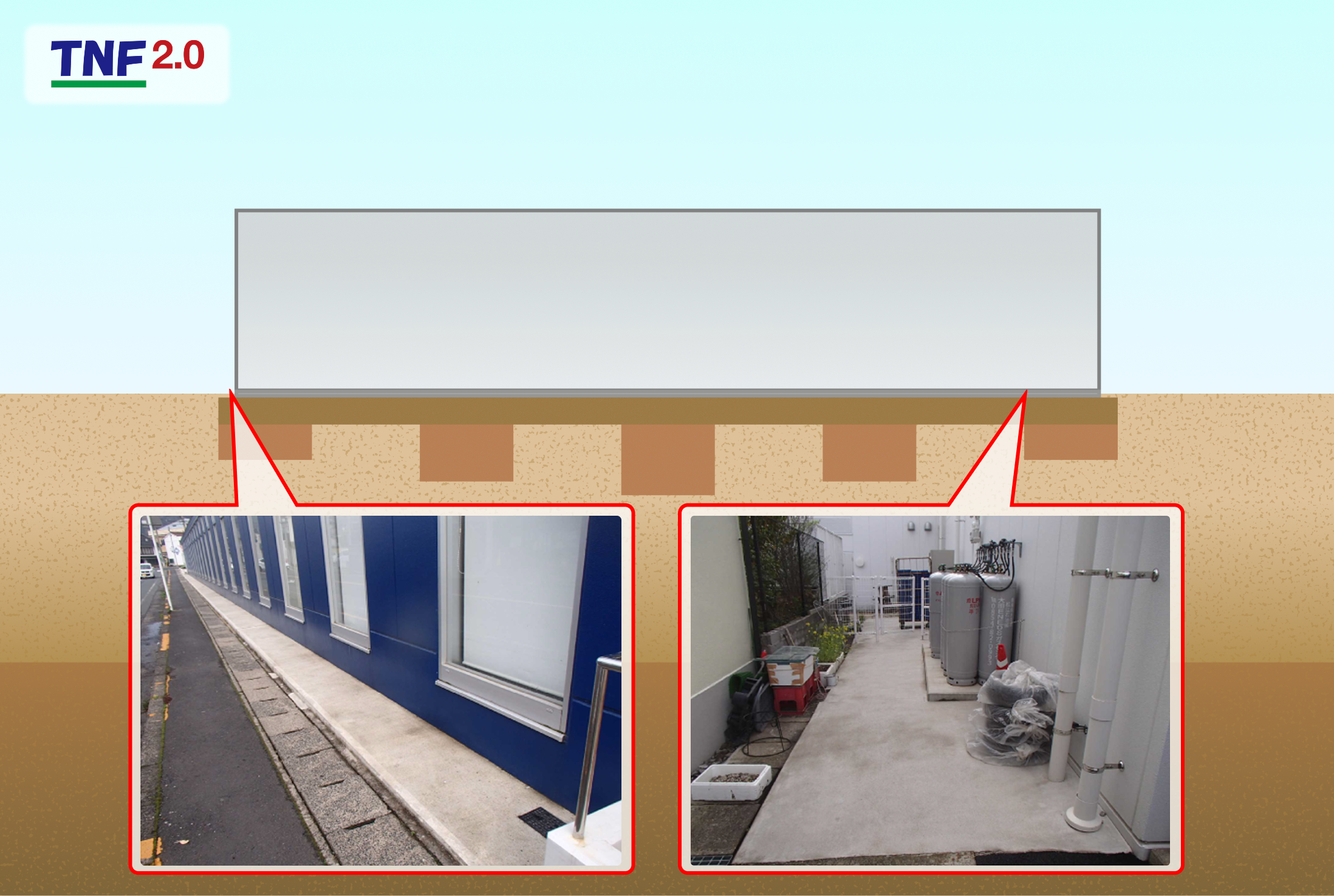

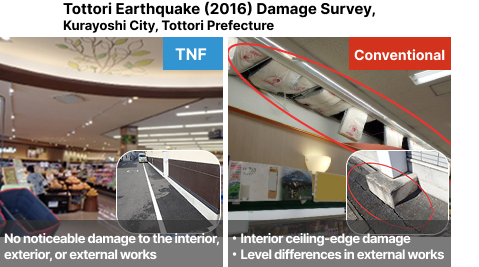

POINT 1. No level differences occurred

- No level differences occurred in the surrounding ground due to differential settlement. Therefore, no repair of level differences was required.

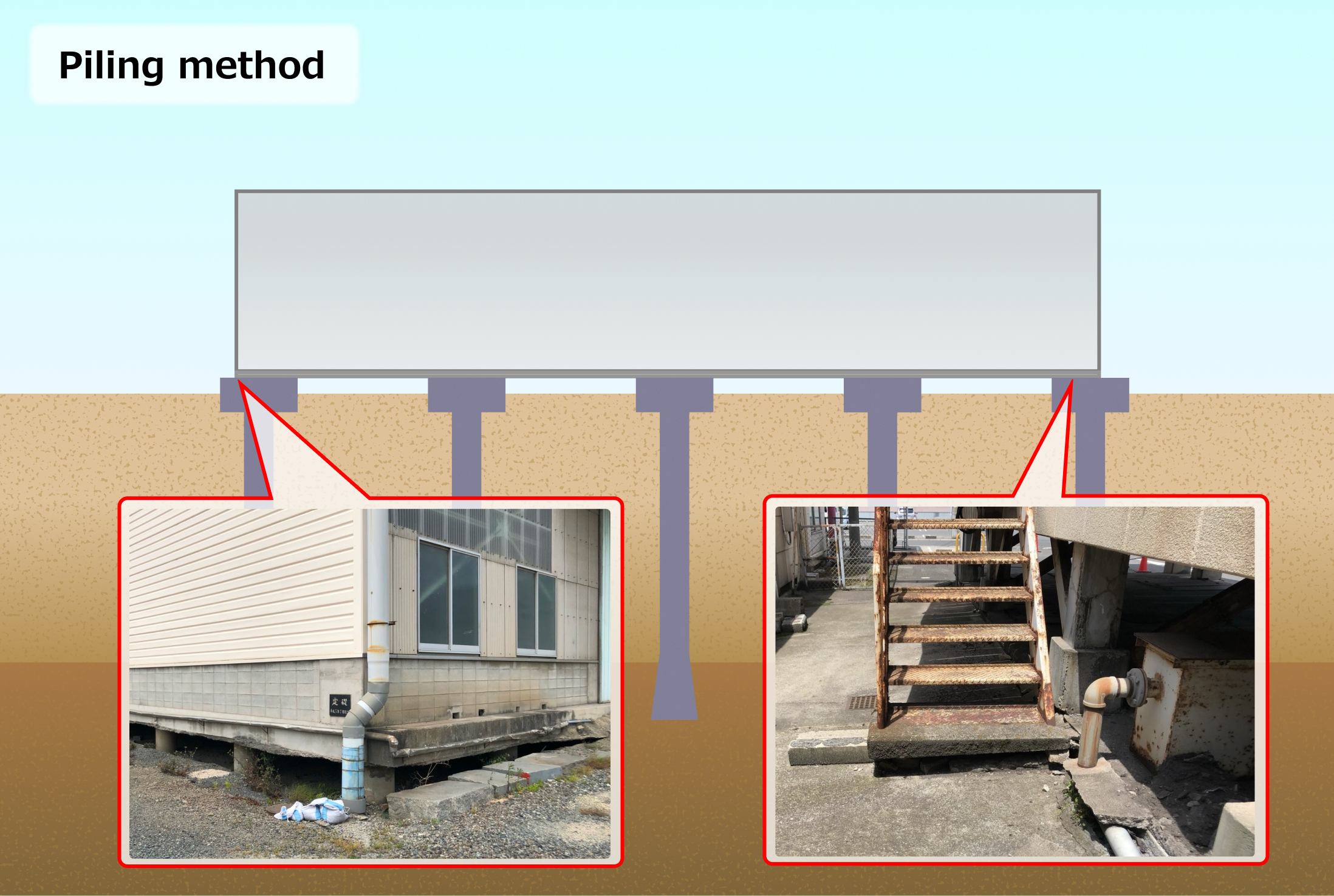

- Level differences are observed in the surrounding ground.

POINT 2. Underground utility piping is protected

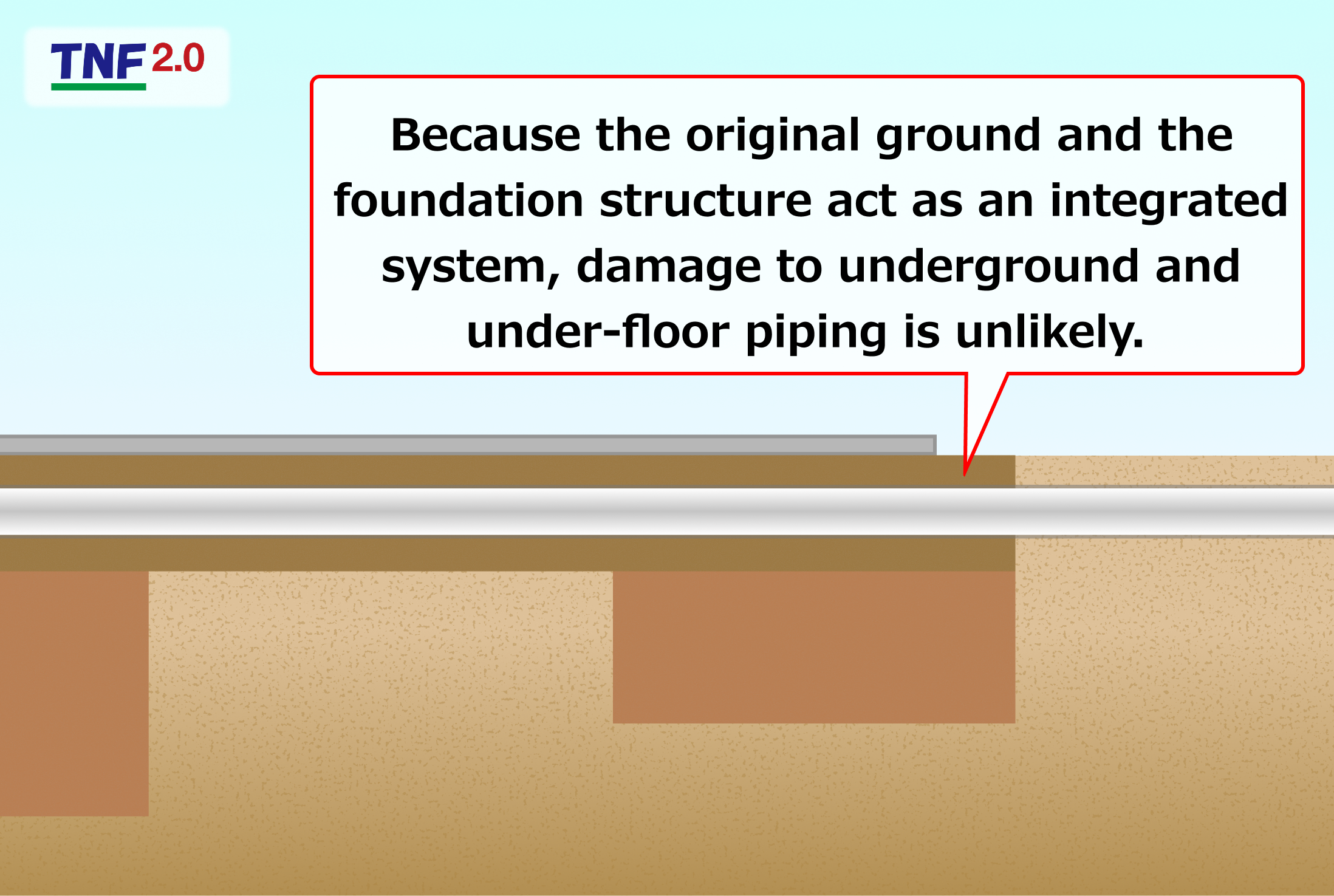

- Because the TNF system integrates the ground and the foundation into a single structure, it prevents level differences caused by differential settlement, thereby helping to avoid damage or breakage of underground and under-slab piping.

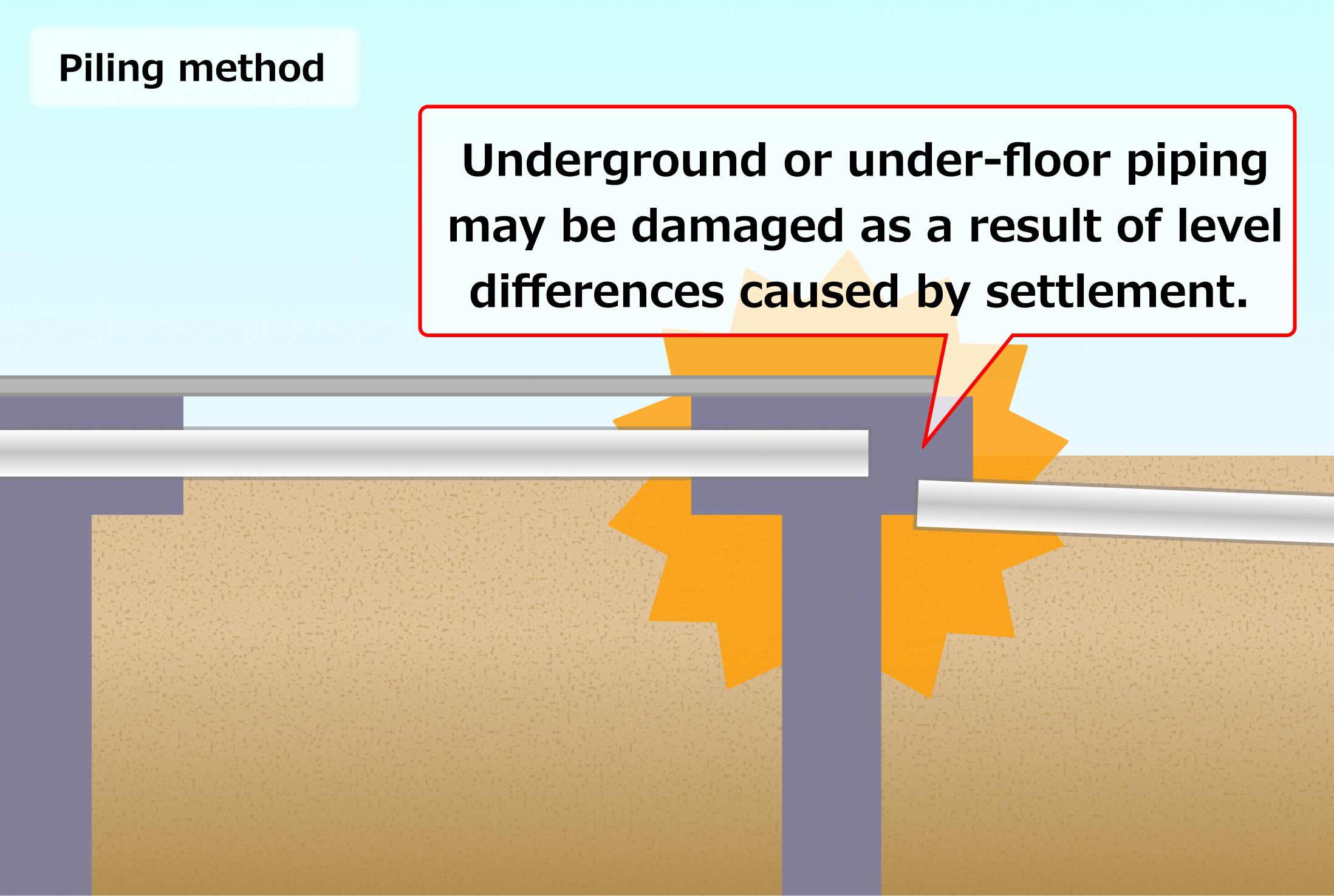

- Breakage of underground or under-slab piping can occur. If such damage occurs, the building may become non-functional.

POINT 3. Removal is simple and low-cost

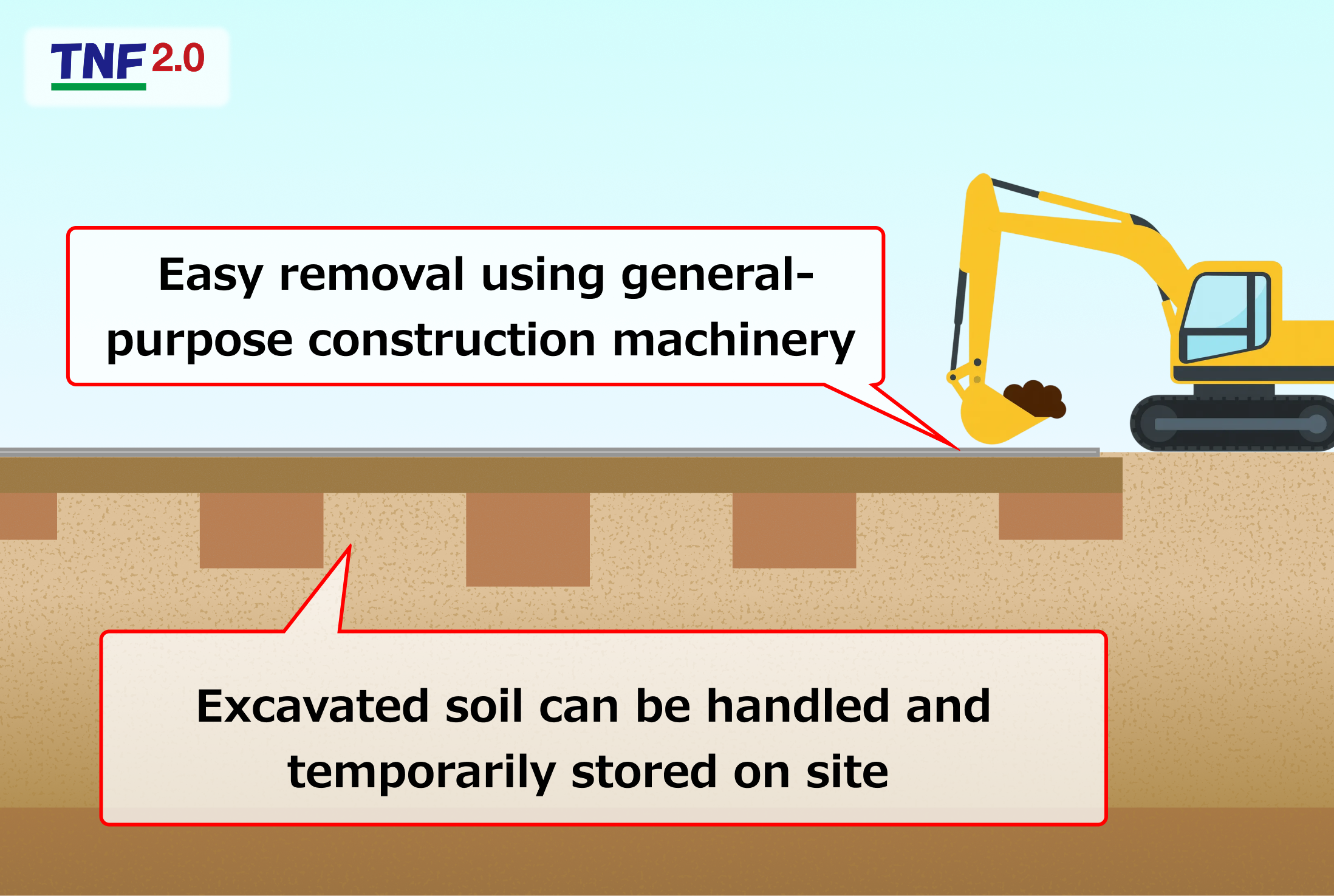

- Removal can be carried out simply by crushing the improved ground body. The resulting soil can be reused or retained on site.

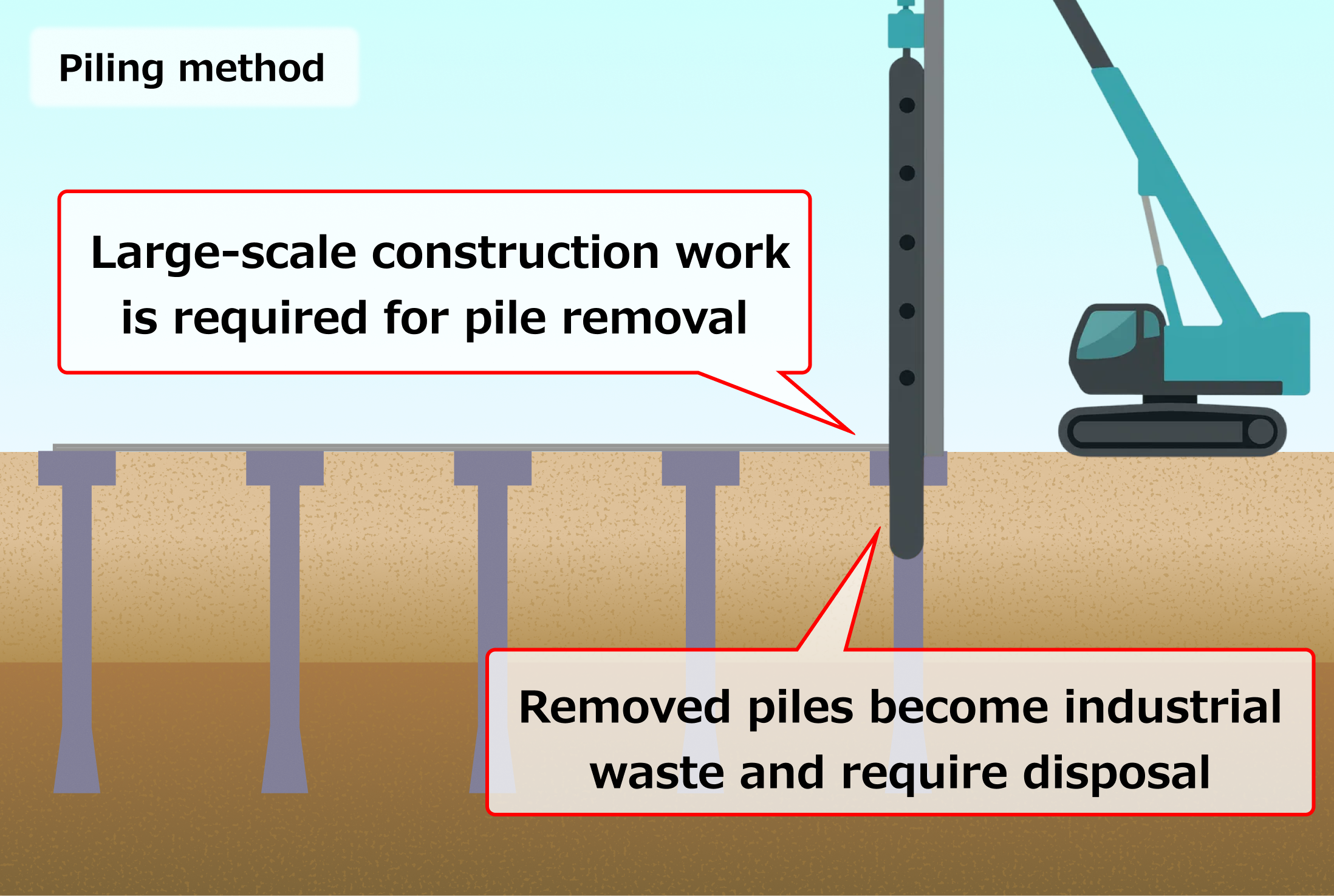

- During removal, pile extraction is required, resulting in additional disposal costs.

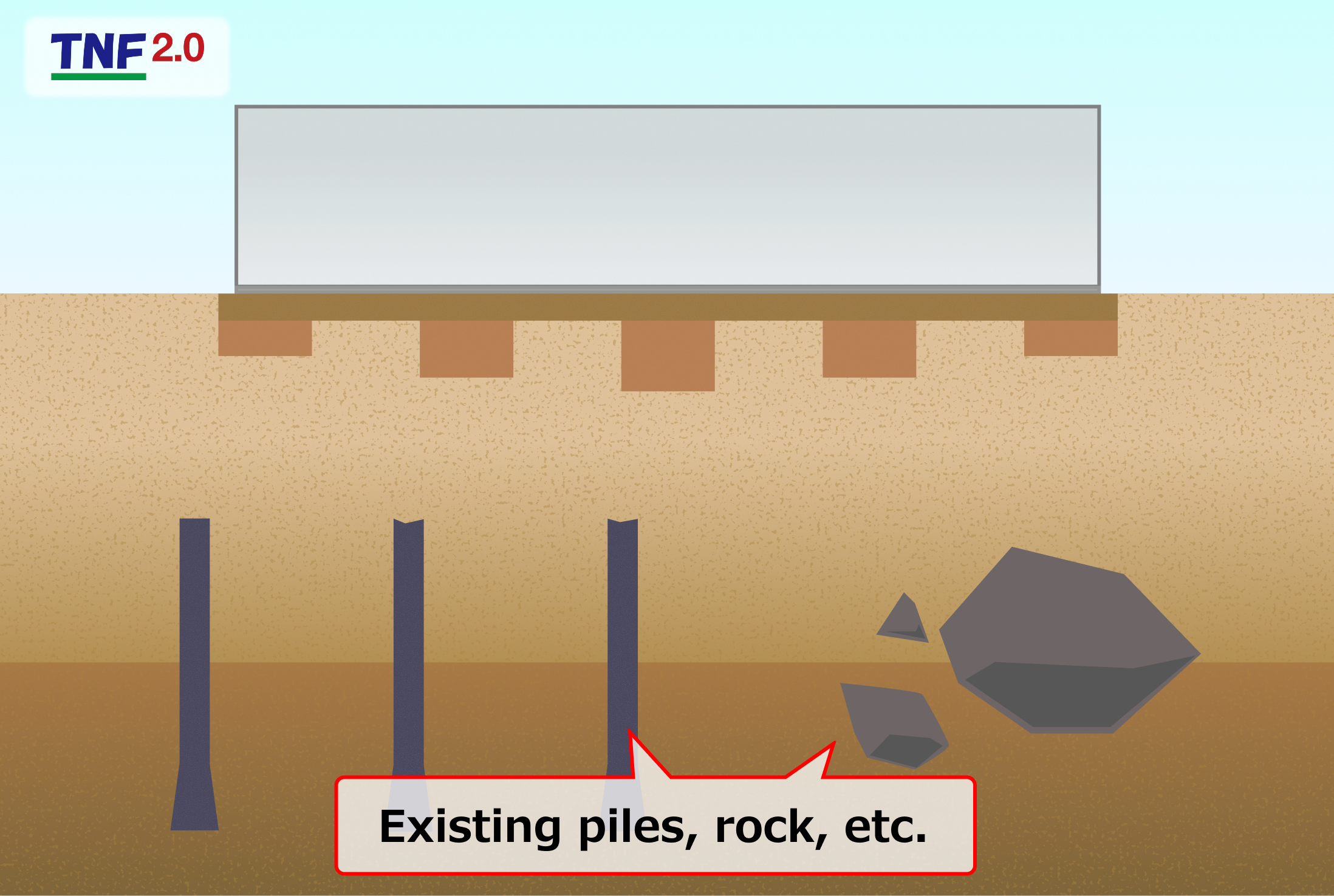

POINT 4. Minimal impact on the underground environment and buried objects

- In rebuilding projects, existing piles may be present; however, the TNF system allows construction to proceed while leaving the piles in place.

(Pile heads and foundations are removed to a depth of approximately 3–4 meters below ground level.)

- Piles cannot be installed in areas where underground archaeological remains or industrial waste are present.

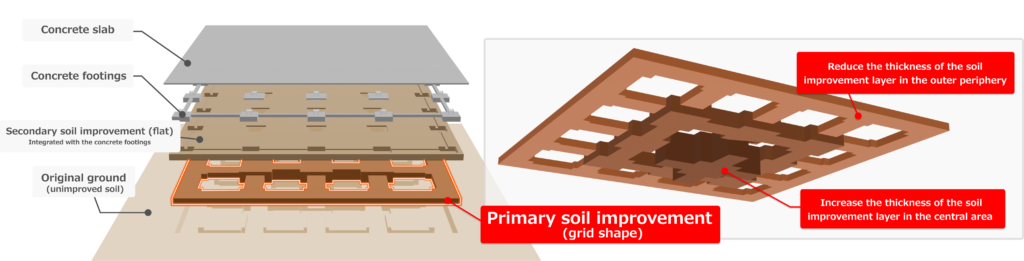

Composition of the Soil Improvement Body

Soil improvement is divided into two stages: primary improvement and secondary improvement.

Primary Improvement

In the primary improvement stage, the original ground is left in place, and grid-shaped improvement is carried out to enclose it.

In particular, deeper improvement is applied in the central areas of the building, where the applied loads are greater.

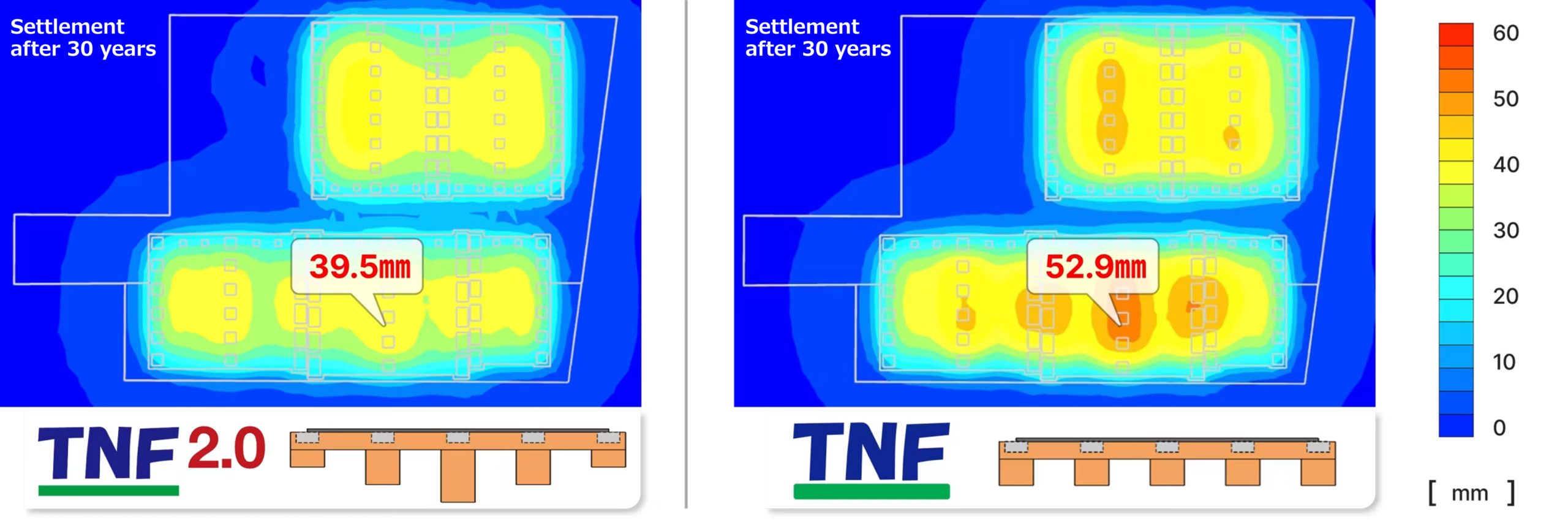

● Suppression of Differential Settlement

Compared with the conventional TNF system, in which the depth of the primary improvement is uniform, the TNF 2.0 system has been confirmed to effectively suppress both average and differential settlement.

For detailed analysis examples, see here: Ground Analysis by FEM

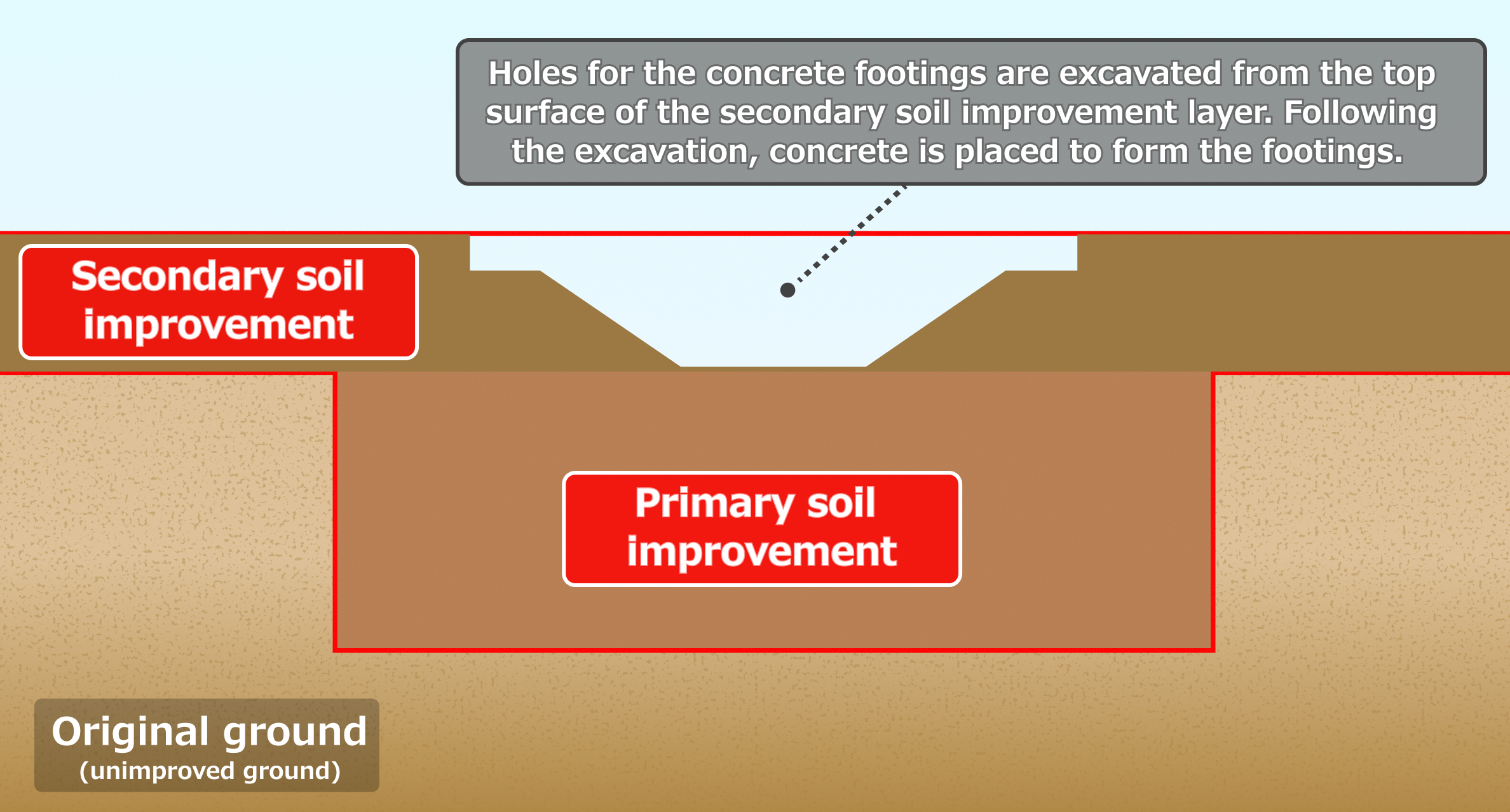

Secondary Improvement

In the secondary improvement stage, the entire area beneath the building is improved to a depth of approximately 1 meter. Because the ground beneath the slab is improved, no slab reinforcement is required.

● No Formwork Required

By excavating the secondary soil improvement layer, the soil improvement body serves as concrete formwork. Since the footing concrete can be placed directly, formwork costs can be reduced.

For details, see here: TNF-DD Method

Features of the TNF system and Its 11 Advantages

➀ Shortened Construction Period

Because concrete footings reinforcement, slab reinforcement, and footings formwork are completed in a single continuous process, the number of work stages is reduced, enabling a shorter construction period.

➁ Reduced Use of Building Materials

The soil improvement body provides stable support for the concrete footings.

Ground beams are unnecessary, significantly reducing concrete and rebar work.

Since concreting work can be placed directly onto the soil improvement body, formwork is basically unnecessary.

➂ Low Temporary Construction Costs

Work platforms are formed as part of the soil improvement work, eliminating the need for full-area steel plates.

After construction, the improved ground surface allows access by vehicles such as truck-mounted cranes, thereby reducing material handling and lifting costs.

-1.png)

④ Fewer Work Types (Earthwork Only)

With the TNF system, concrete footings reinforcement, slab reinforcement, and footing formwork can all be carried out in an integral manner.

In recent years, securing formwork carpenters has become increasingly difficult; however, with the TNF system, footings formwork is generally unnecessary.

⑤ Construction Using General-Purpose Equipment

The TNF system does not require specialized machinery and can be implemented using readily available general-purpose construction equipment, enabling prompt commencement of work.

➅ Less Excavated Soil and a Cleaner Construction Site

With a pile foundation method, excavated soil often becomes muddy and must be treated as construction waste. In contrast, excavated soil generated by the TNF system is high-quality improved soil that can be reused, for example, beneath slabs. The volume of surplus soil can be reduced to less than half that of pile foundation method. In addition, the site remains orderly after construction, facilitating material transport and temporary storage. Because workers are not hindered by muddy ground conditions, work efficiency is improved and safety is enhanced.

➆ Easy Demolition Work

With pile foundation method, the cost of pile removal can be as much as three times the installation cost. In contrast, with the TNF system, the improvement body can be crushed to a specified size and left in place as high-quality ground, eliminating the need to remove piles.

➇ Suppression of Level Differences and Enhanced Seismic Resistance

During earthquakes, the improved layer acts as a protective layer against liquefaction. Past events, such as the Great East Japan Earthquake and the Kumamoto Earthquake, have confirmed that damage was minor compared to buildings supported by equivalent pile foundations.

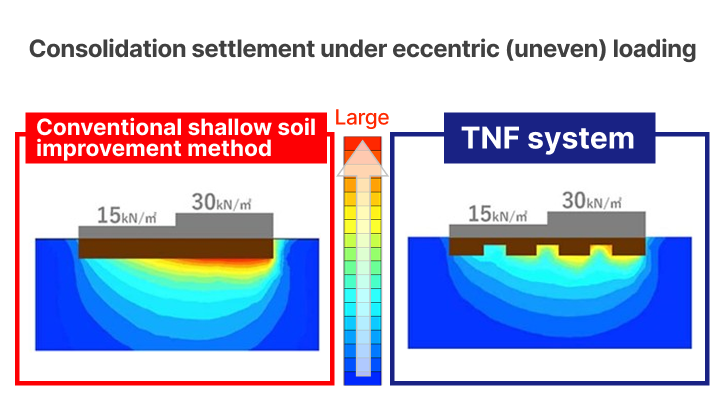

⑨ Strong Resistance to Differential Settlement

Compared with conventional shallow soil improvement methods, the TNF system forms a grid-shaped base that effectively disperses stress, even when loads are unevenly applied. This reduces overall settlement and makes differential settlement less likely. Furthermore, even if uneven settlement occurs, the rigid ground improvement body of the TNF system can resist the reaction forces from fillers. By injecting urethane resin between the slab concrete and the ground improvement body, the slab can be lifted and surface unevenness can be corrected.

⑩ Ground Guarantee

For ground improvement works carried out by this association, insurance based on the Product Liability (PL) Law is applied.

⑪ Minimal Impact on the Underground Environment and Buried Objects

Construction can be carried out without damaging natural environments such as groundwater veins. The TNF system also enables construction without disturbing buried cultural properties and can be applied at sites that require industrial waste treatment.

Related Articles