Construction-to-Demolition Lifecycle

- Home

- Environmental Initiatives

- Construction-to-Demolition Lifecycle

An Environmentally Conscious Foundation Method from Construction to Demolition

The TNF 2.0 method is an environmentally conscious construction method not only during construction, but also at the time of building removal and reconstruction.

Table of Contents

Environmental Considerations During Construction

Reduction of Excavated Surplus Soil

With conventional pile foundation methods, much of the surplus soil generated during excavation becomes muddy sludge, which must be treated as construction waste.

In contrast, the TNF method produces high-quality improved soil, making it suitable for reuse on site.

Column improvement and pile methods: soil has a sludge-like, viscous consistency

This improved soil can be reused as subfloor fill material or for exterior works, reducing the volume of surplus soil to less than half that of pile foundation methods.

This simultaneously reduces disposal costs and environmental impact.

Reduced CO₂ Emissions Through Shorter Construction Periods

The TNF 2.0 method does not require large-scale construction work like pile foundations and can be executed using standard construction machinery, shortening equipment procurement time.

In addition, concrete can be placed directly on the improved ground with minimal formwork, enabling shorter construction periods.

As a result, CO₂ emissions can be reduced through shortened construction schedules.

Construction Using Standard Machinery

No specialized machinery required, enabling shorter construction periods and lower costs

No Formwork Required

Concrete can be placed directly on the improved ground, reducing the amount of formwork required

No Temporary Work Costs

Temporary working platforms are created during ground improvement, eliminating the need for full-site steel plates

Demolition of the TNF 2.0 Method

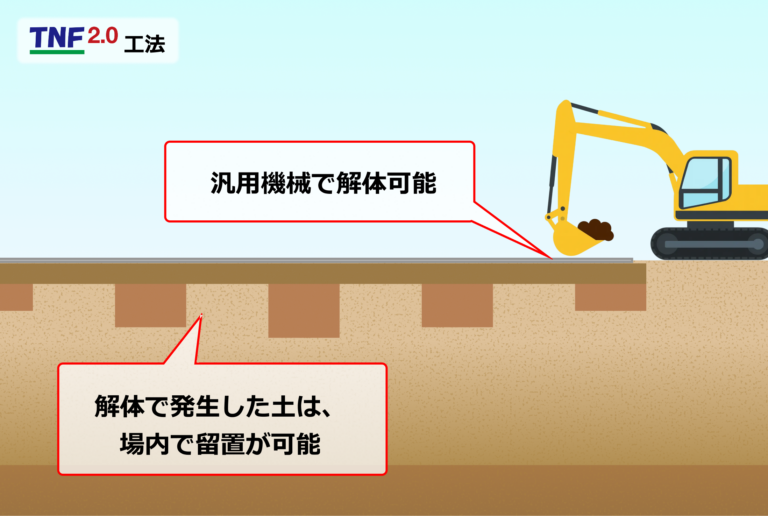

Easy Demolition of Improved Ground

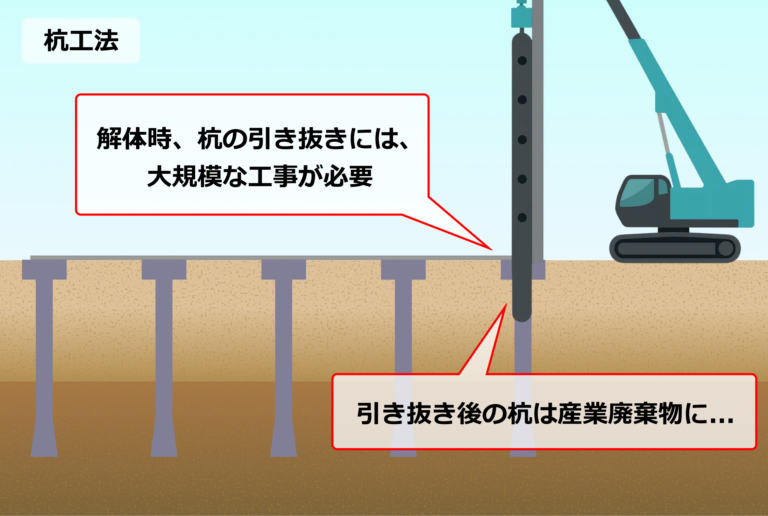

With conventional column improvement and pile foundation methods, large-scale work such as pile extraction is required during demolition, and removal costs can reach approximately three times the original construction cost.

In contrast, the TNF method requires work only to a shallow depth of approximately 2–3 meters below ground level, allowing demolition using standard machinery. As a result, removal and demolition costs can be reduced to about half of the original construction cost.

Reduction of Industrial Waste Through Reuse of Excavated Material

The improved ground material generated during demolition can be finely crushed and reused as construction soil.

According to the Ministry of Land, Infrastructure, Transport and Tourism (MLIT) standards for construction-generated soil utilization, soil produced from TNF ground improvement meets or exceeds Class 3 construction soil criteria and can be used as backfill material without additional treatment.

This makes it possible to suppress the generation of industrial waste while reducing environmental impact and achieving high cost performance.

Benefits During Reconstruction

With the TNF method, the improved soil generated during demolition can be reused on site as backfill material, maintaining good ground conditions after demolition.

As a result, the amount of solidifying agents required for ground improvement during reconstruction can be reduced.

In this way, the TNF method is a ground improvement technology that achieves both environmental performance and economic efficiency throughout the entire lifecycle—from construction to demolition and reconstruction.

Demolition Procedure for Improved Ground

Demolition case study

Use: Supermarket

Completion: May 2011

Demolition: October 2019

Crushing of Slab and Improved Ground

The improved ground is broken using an excavator, and large masses are divided into smaller pieces.

Crushing of Large Blocks

A nibbler (lightweight crusher) is used to further break down large blocks.

Crushing to Below the Specified Size

When necessary, a self-propelled jaw crusher is used to crush material to below the specified size.

Backfilling with Demolition-Generated Soil

The finely crushed soil produced through the above steps is reused on site as backfill material.

This maintains favorable ground conditions and reduces ground improvement costs during reconstruction.

In addition, reductions in imported soil and industrial waste volumes contribute to overall cost savings.